1.Full automatic working, automatic lifting edge cutter cutting;

Quilting Series

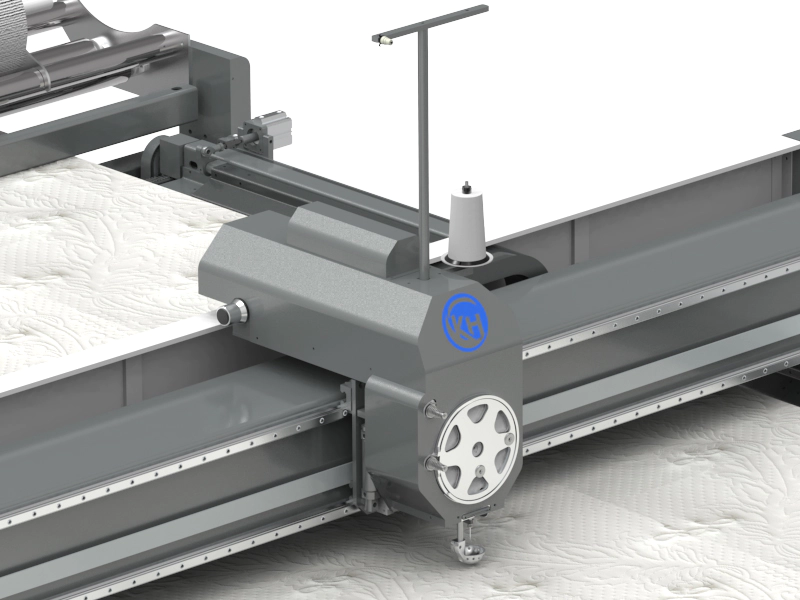

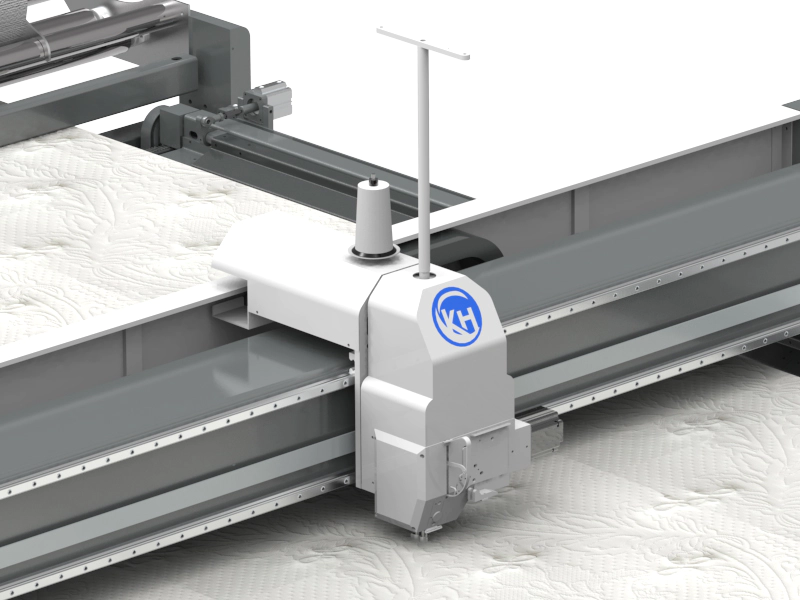

KH-V1A / DK1S Full-Auto Single-Needle Quilting Machine

5.0

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Technical parameters

| V1A | DK1S |

Quilting Thickness | ≤100mm | ≤80mm |

Quilting Width | ≤2400mm | |

Rotating Speed Of Needle | 3200RPM | |

Stitch Length | 2-6mm | |

Overall Dimension | 9300x3685x1980mm | |

Total Weight | 2500kg | |

Power Supply | 380V,50HZ | |

Total Power | 8.5KW | 5.5KW |

Product Main Information

2.Auto thread trimming, auto-stop when thread-breaking, patterns auto-positioning amending after thread-breaking;

3.Output counting, pattern effect display, processing locus display functions;

4.Professional pattern-designing software, scanner-input patterns with BMP format, CAD method pattern designing;

5.Real time data protection, operation continuing in original position after sudden power shortage;

6.360°jump quilting, large capacity patterns storage system(up to 100.000 and above patterns).

Details of the figure

Patterns figure

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Leave us your message

If you are interested in our products or service, please contact us at.

Related Products

no data